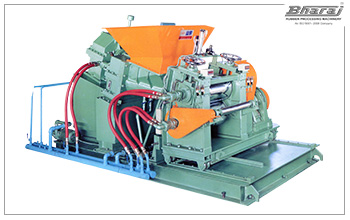

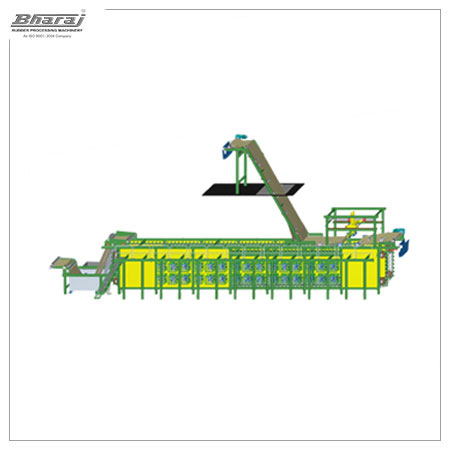

TWIN SCREW RUBBER SHEETER

Twin Taper Screw Roller Head Extruder, is normally installed at the downstream of mixer. The material

after being mixed can be dropped directly in this extruder and be extruded automatically into sheet material. Easy and continuous operation function makes it the best equipment for automation. The machine consists of two taper screw unit and two rollers unit. Easy construct makes it easy for maintenance. When material is being mixed by two taper screws, low inner mixing pressure and excellent cooling effect ensures the stability of physical characteristics and quality of materials. Mass production, saving of time, saving of power.